Step 9 – Frame the Floor

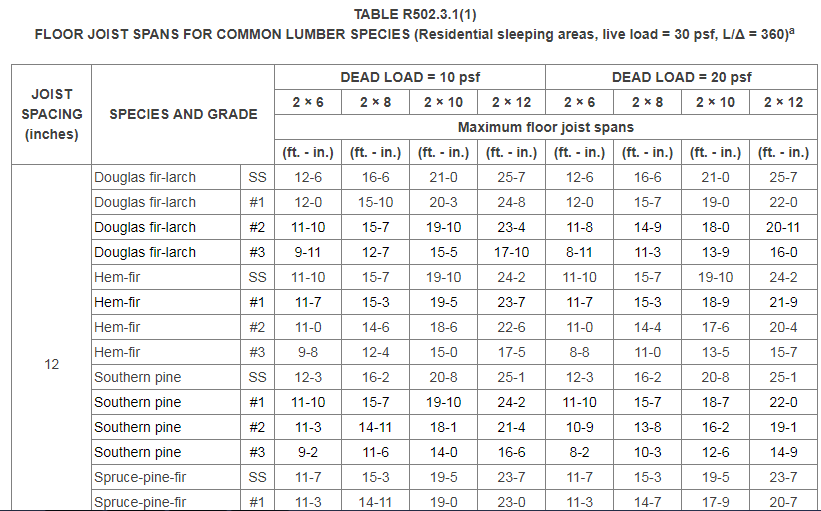

Proper joist sizes can easily be figured out from the IRC (International Residential Building Code) using a table in the same way you calculate header sizes. For me, that meant looking at the part of the table that dealt with 24 inch joist spacing since that is what I’m using. Then figure out what the greatest distance the joists will span is, which for me is just slightly over 14 feet. Last, select a lumber option that supports a minimum span greater than this distance. I decided to go with #2 2×12 Douglas Fir, which supports a span of up to 16’6″. Going with an option suitable for a span larger than what I need will hopefully give me a less bouncy, less squeaky floor.

Lifting 16 foot 2×12’s 10 feet up in the air solo is a great workout. After cutting each joist to length. I lifted one side up in the air and rested it on the top of an exterior wall. Next I moved a ladder near the interior bearing wall and lifted the other end of the joist up so I could rest it on the top of the ladder. After climbing up a few rungs on the ladder, I had enough height where I could lift the joist from the top of the ladder to rest on the interior wall. Just as with the wall framing, it was important to ensure that the crown of the lumber faced the sky.

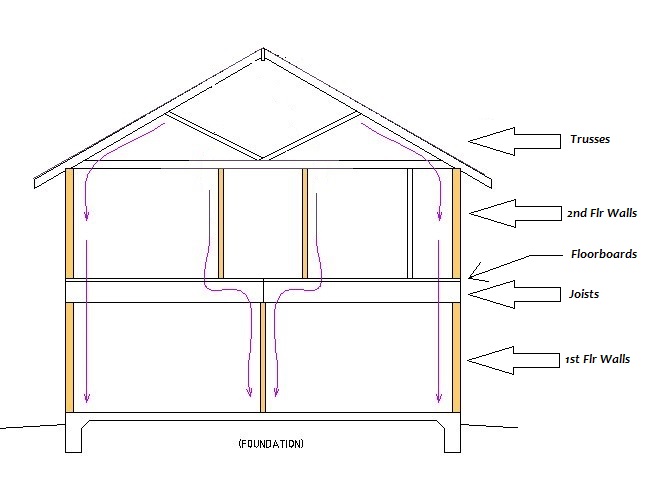

The first joists I installed are called the rim joists. These run on the top of the exterior walls perpendicular to the rest of the joists. Above you can see the rim joist on the left side of the corner and the outermost floor joist on the right side. Using rim joists ensures that there is a perimeter of joists all the way around the house even though the majority of the joists run in the same direction. The rim joists are “toe-nailed” to the top plate, meaning that they are nailed diagonally. Once the rim joists are up, the other joists are placed perpendicular between them and nailed to the rim joists, as well as toe-nailed to the exterior walls.

The opening for the stairway required a little bit of detail. The code requires joists to be doubled all around the opening. In addition, any time you are unable to rest a joist on a bearing wall, you must use steel joist hangers to carry the weight around to where it can reach a bearing wall. The manufacturer of the hangers (in this case Simpson Strong-Tie) tells you what kind of nails you must use and what amount of weight the hanger is capable of carrying.

Advice? Questions? I'd love to hear your feedback or help you out in any way I can!